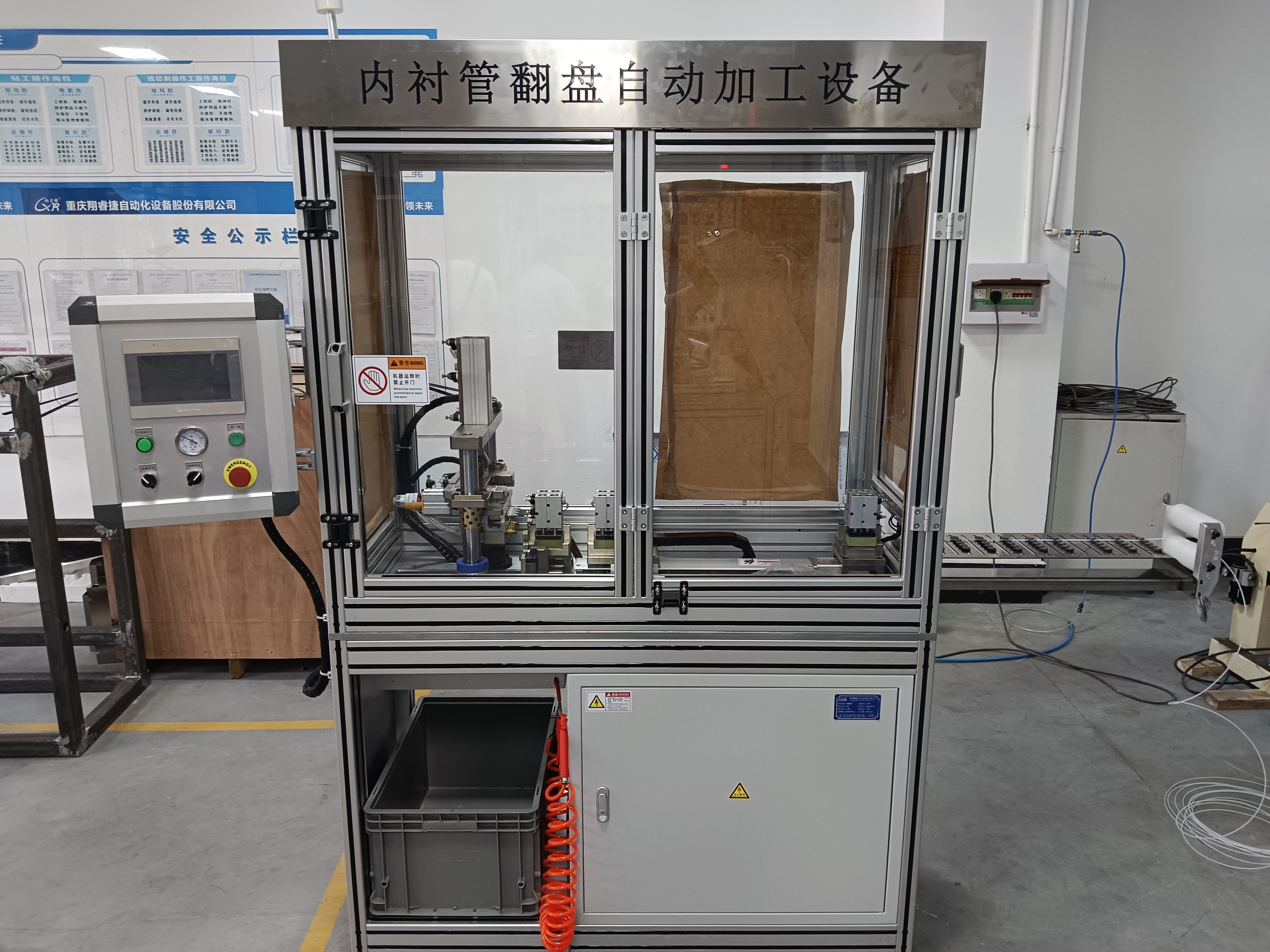

拉索螺桿鉚壓綜合一體機(jī)

1)電源220V、50Hz,氣源0.5-0.7Mpa;

2)適用于套管類型:本設(shè)備適用于φ5-φ6-φ7彈簧軟管或直絲管,保證管子直線度;

3)適用于鋼絲繩類型:本設(shè)備適用于φ1.5-1*19、φ1.8-1*19、φ2.0-1*19、φ2.5-1*19鋼絲繩;

4)加工產(chǎn)品尺寸范圍:壓力管長(zhǎng)度范圍900mm-1900mm、A+B長(zhǎng)度范圍42mm-242mm,精度±1mm;產(chǎn)品極限總長(zhǎng)度:942mm-2142mm(不包含螺桿接頭長(zhǎng)度尺寸);

5)帶防塵套產(chǎn)品加工要求:需滿足A+B長(zhǎng)度尺寸大于(42mm加上防塵套自然狀態(tài)下長(zhǎng)度尺寸);

6)螺桿零件要求:螺桿外形整體通圓無方盤,規(guī)格M5、M6,長(zhǎng)度65-68±1mm,螺桿內(nèi)孔倒角60度,倒角圓潤(rùn)無飛邊快口,內(nèi)孔與外徑保證同心度小于0.1mm;

7)壓鉚力:15T,壓鉚總行程:100mm,增壓行程:15mm;

8)精切機(jī)構(gòu)剪切力:5000N;

9)拉脫力檢測(cè)參數(shù):氣壓0.3Mpa出力1300N±50N,氣壓0.6Mpa出力2700±50N,拉力傳感器最大量程0-500Kg,精度0.3%;

10)A+B行程檢測(cè)參數(shù):檢測(cè)力50N±10N,拉力傳感器最大量程0-50Kg,精度0.3%,位移傳感器量程0-100mm,精度0.3%,分辨率0.02mm,檢測(cè)氣缸行程0-60mm;

11)產(chǎn)品分選容量100套;批次分選數(shù)量自由可調(diào);

12)產(chǎn)品數(shù)據(jù)儲(chǔ)存100萬組,可導(dǎo)出;

13)產(chǎn)品報(bào)廢率不大于1%,因產(chǎn)品零件質(zhì)量問題不計(jì)入產(chǎn)品報(bào)廢率;

14)設(shè)備動(dòng)作1個(gè)循環(huán)周期時(shí)間不大于5s,不包含人工裝件時(shí)間;

15)設(shè)備更換產(chǎn)品工裝調(diào)整時(shí)間不大于15分鐘,按熟練工人測(cè)算;1) power supply 220V, 50Hz, air source 0.5-0.7mpa;

2) applicable to the type of casing: this device is applicable to 5-6-7 spring hose or straight wire tube, ensuring the straightness of the pipe;

3) suitable for wire rope type: this equipment is suitable for the 19, phi phi 1.5 1 * 1.8 1 * 19, 19, phi phi 2.0 1 * 2.5 1 * 19 wire rope;

4) size range of processed products: pressure tube length range 900mm-1900mm, A+B length range 42mm-242mm, accuracy ±1mm;Total product limit length: 942mm-2142mm (not including screw joint length and size);

5) processing requirements for products with dust jacket: A+B length shall be met if the size is larger than (42mm plus the length of dust jacket in the natural state);

6) screw parts requirements: screw overall shape through a round non-square plate, M5, M6, length of 65-68±1mm, screw hole chamfering 60 degrees, chamfering round no flash flash, inner hole and outer diameter to ensure the concentricity of less than 0.1mm;

7) riveting force: 15T, total riveting stroke: 100mm, pressurized stroke: 15mm;

8) shear force of fine cutting mechanism: 5000N;

9) tensile force detection parameters: air pressure 0.3mpa output 1300N±50N, air pressure 0.6mpa output 2700±50N, maximum range of tension sensor 0-500kg, accuracy 0.3%;

10)A+B stroke detection parameters: detection force 50N±10N, maximum range of tension sensor 0-50kg, accuracy 0.3%, displacement sensor range 0-100mm, accuracy 0.3%, resolution 0.02mm, cylinder stroke 0-60mm;

11) product sorting capacity of 100 sets;Batch sorting quantity is freely adjustable;

12) 1 million sets of product data can be stored and exported;

13) the scrap rate of products shall be no more than 1%, and shall not be included in the scrap rate due to quality problems of product parts;

14) the time of one cycle of equipment action should be no more than 5s, excluding the time of human tooling;

15) the adjustment time of equipment replacement and tooling shall be no more than 15 minutes, calculated by skilled workers;

關(guān)鍵詞:

拉索螺桿鉚壓綜合一體機(jī)

所屬分類:

詳情描述

設(shè)備集成了精切、鉚壓、拉脫力檢測(cè)、有效行程檢測(cè)、產(chǎn)品合格品與不合格品分選、產(chǎn)品數(shù)量批量?jī)?chǔ)存等動(dòng)作。與傳統(tǒng)的分離式工藝相比,本設(shè)備有保證產(chǎn)品質(zhì)量、提高生產(chǎn)效率、及減少人員配置的優(yōu)點(diǎn);設(shè)備工位移動(dòng)機(jī)構(gòu)采用整體同步行進(jìn),保證了產(chǎn)品級(jí)進(jìn)精度和可靠性,設(shè)備采用人機(jī)控制界面,實(shí)現(xiàn)參數(shù)化可視控制,方便生產(chǎn)員工根據(jù)實(shí)際生產(chǎn)需求更改相應(yīng)參數(shù),產(chǎn)品檢測(cè)數(shù)據(jù)具有后臺(tái)儲(chǔ)存功能,設(shè)備故障可顯示根據(jù)理論時(shí)間節(jié)拍分析,生產(chǎn)節(jié)拍預(yù)估為:6s/件,8小時(shí)班產(chǎn)量:4800件設(shè)備使用電器元器件、電氣控制元件均采用國內(nèi)外知名品牌,保證設(shè)備運(yùn)行精度及穩(wěn)定性;設(shè)備合理的調(diào)試、維護(hù)門的設(shè)計(jì),更好的實(shí)現(xiàn)后期設(shè)備的調(diào)試和維護(hù);

The equipment is integrated with precision cutting, riveting, pulling force testing, effective stroke testing, product qualification and non-qualification product sorting, product quantity batch storage and other actions.Compared with the traditional separation process, this equipment has the advantages of ensuring product quality, improving production efficiency and reducing personnel allocation.Equipment location mobile mechanism adopts whole synchronization, ensure the product level into the accuracy and reliability of equipment is controlled by the man-machine interface, realize the parametric visual control, convenient to change the corresponding parameter according to actual production demand, production staff product testing data with a backend storage function, equipment failure can be displayed according to the theory of time rhythm analysis, produce the beat forecasts for: 6 s/a, 8 hours of class output: 4800 pieces of equipment used electrical components, electrical control components all use well-known brands at home and abroad, to ensure the precision and stability of equipment operation.Equipment reasonable debugging, maintenance door design, better realize the late equipment debugging and maintenance;

相關(guān)設(shè)備