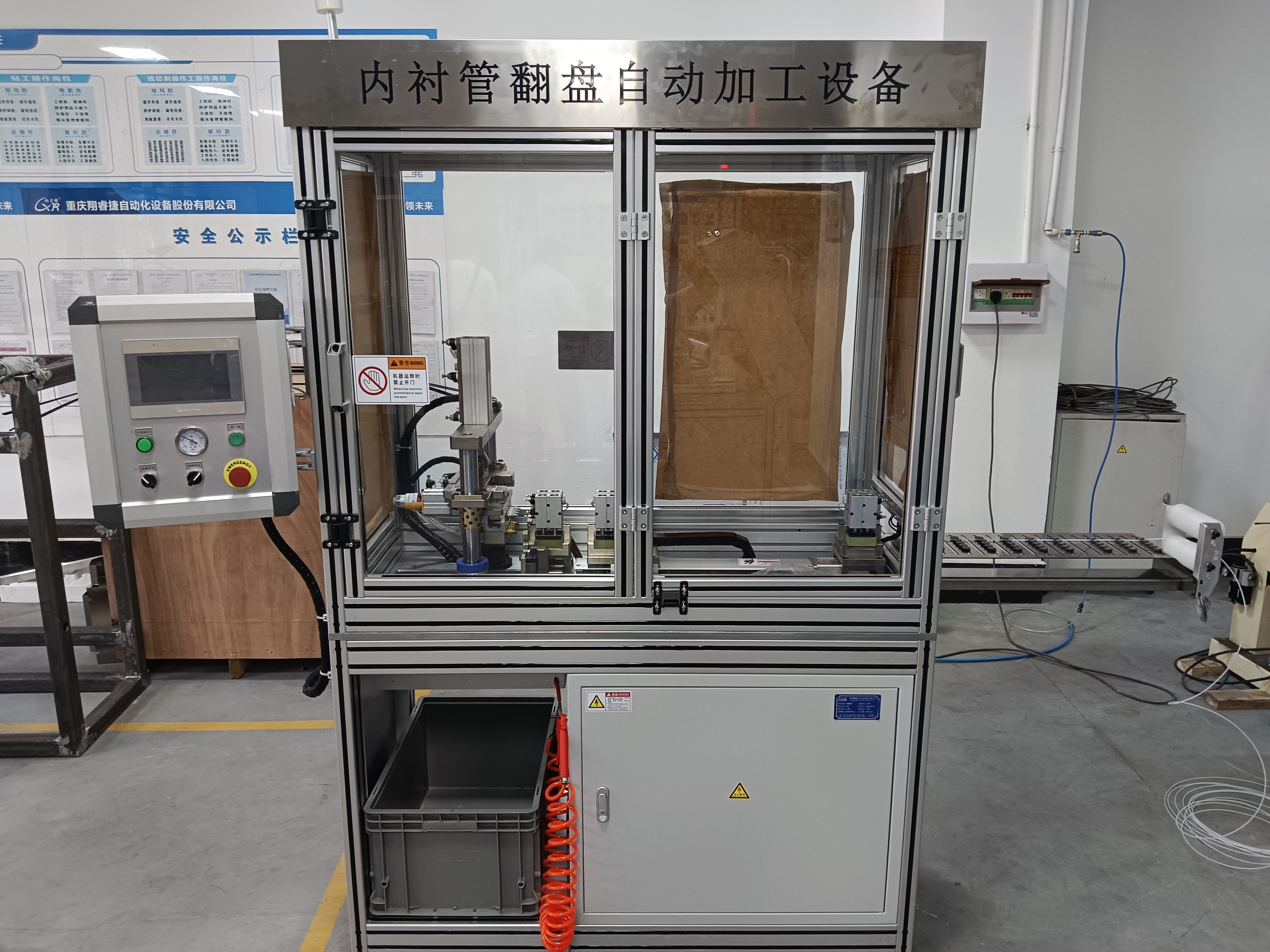

拉索裝配生產流水線

關鍵詞:

所屬分類:

詳情描述

Meet the assembly requirements of single and double push cables (products and processes)

Each station adopts manual feeding and manual discharging, and the stainless steel groove hanging chute is used for alternating conveying between stations

The production line adopts the principle of single piece flow, and the buffer design between stations is 1-5 pieces.

The production line is designed with a total of 10 stations (including packaging), each station is basically balanced, the time tempo of each station is 20S/ set, and the output is 1440 sets per 8 hours per day.

Proper application of error-proof technology to the parts that are easy to be misfitted, misfitted, and backloaded, and error-proof monitoring shall be carried out.

After the completion of each process, the corresponding assembly characteristics (wrong and missing installation, whether in place, operation performance, etc.) should be manually self-checked and marked accordingly

Final inspection set up appearance testing platform: manually confirm the parts, appearance parts, product performance and other items that are easy to be installed by mistake or omission.

According to the process of non - conforming product control, quality management, process management.

Appropriate application of equipment management, safety, ergonomics, rapid change of die line, appearance and other technologies

相關設備